Chrome Plating Corrugated Roll

Product Details:

- Material Metal

- Computerized No

- Control System Human Machine Interface

- Color Silver

- Warranty Yes

- Click to view more

Chrome Plating Corrugated Roll Price And Quantity

- 25000 USD ($)/Set

- 8000.00 - 25000.00 USD ($)/Set

- 1 Set

Chrome Plating Corrugated Roll Product Specifications

- No

- Silver

- Yes

- Metal

- Human Machine Interface

Chrome Plating Corrugated Roll Trade Information

- Tianjin, Qingdao, Shanghai, Ningbo

- Letter of Credit at Sight (Sight L/C) Western Union Paypal Telegraphic Transfer (T/T)

- 20 Set Per Month

- 30 Days

- wooden shipping crate

- Australia North America South America Eastern Europe Western Europe Middle East Africa Central America Asia

- All India

- IOS

Product Description

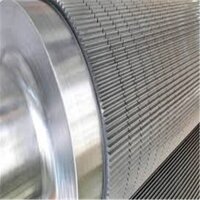

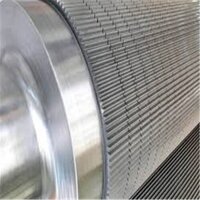

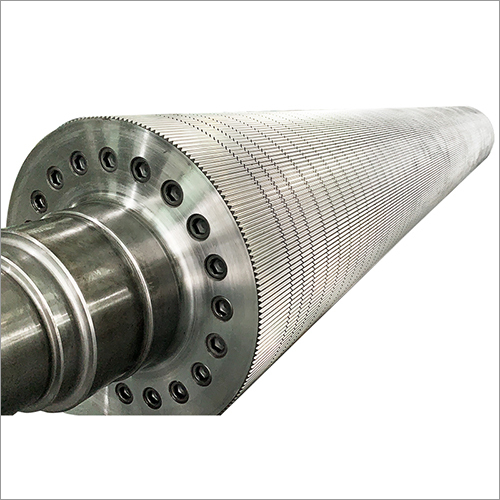

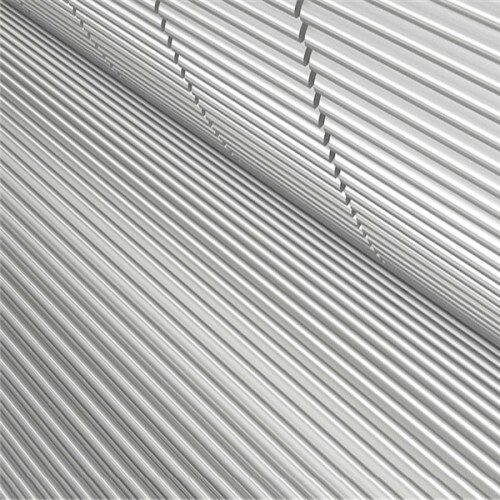

Chrome Plating Corrugated Roll

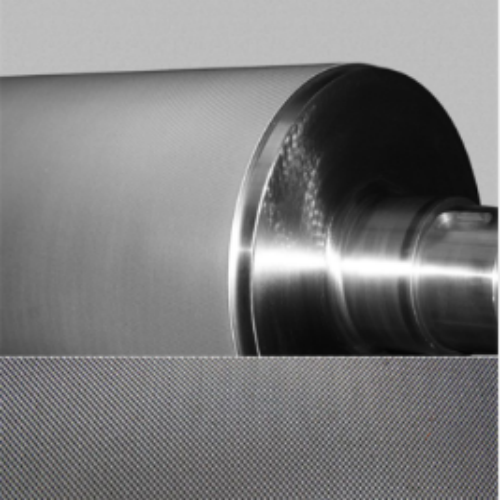

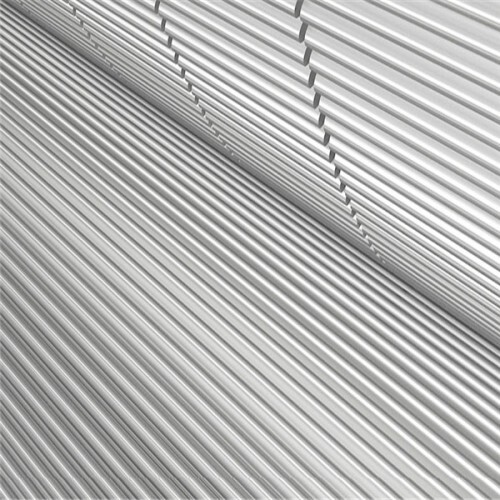

We choose high-quality alloy steel forgings, and the steel has a balanced metal composition to reduce impurities. After heat treatment, corrugated design, roll surface processing technology, surface treatment, surface tungsten carbide coating or surface hard chrome coating, and polishing treatment, a series of processes are produced.

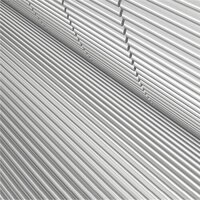

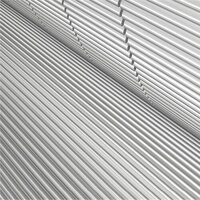

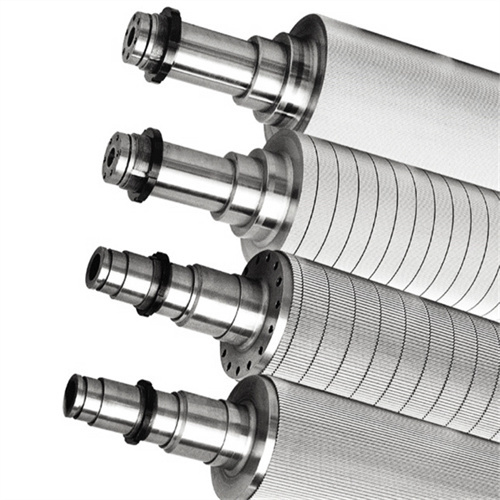

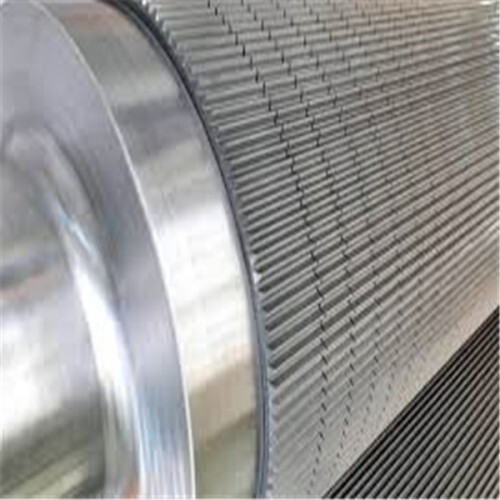

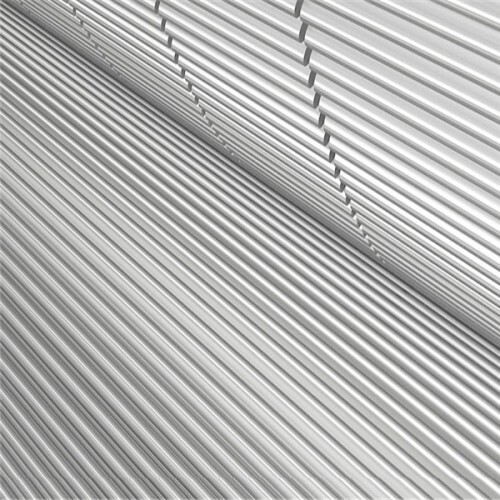

The corrugating roller is used to corrugate the base paper on a single-sided machine. A single facer needs to use two upper and lower corrugating rolls and a pressure roll.

Structure of Chrome Plating Corrugated Roll:

The corrugated roller is made of alloy steel, solid forged, deep hole machine pond hole processing, divided into three parts, roller body, and two shaft heads.

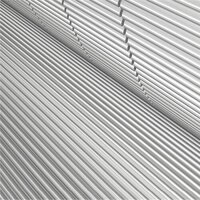

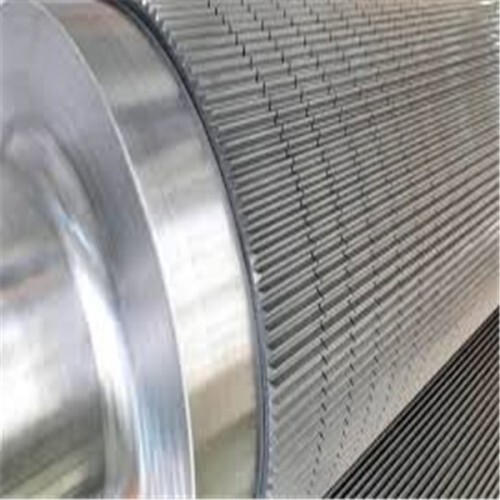

Used on a single facer machine, it is divided into the upper corrugated roller and lower corrugated roller. The upper and lower roller surfaces are tooth-shaped, and the two rollers are matched and assembled.

The function is to form a layer of corrugated core paper on a single-sided machine by paired corrugating rollers.

A combined operation with a glue roller and pressure roller to make one layer of corrugated paper and one layer of paper bonding.