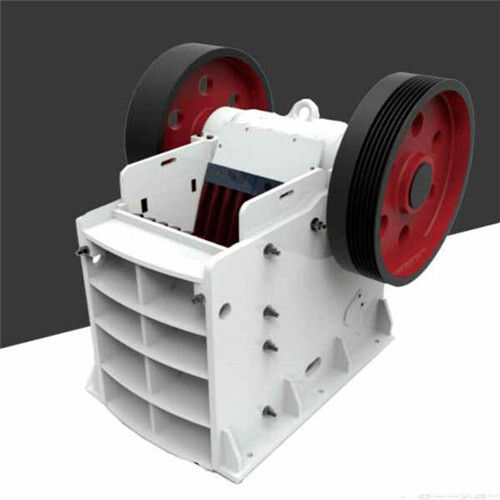

Mining Stone Jaw Crusher

Product Details:

- Type Mining Stone Jaw Crusher

- Material Stainless Steel

- Capacity 1000 Ton/day

- Computerized No

- Automatic Grade Automatic

- Voltage 3000 Watt (w)

- Frequency (MHz) 50 Hertz (HZ)

- Click to view more

Mining Stone Jaw Crusher Price And Quantity

- 5 Set

- 10000.00 - 40000.00 USD ($)/Set

- 15000 USD ($)/Set

Mining Stone Jaw Crusher Product Specifications

- 1000 Ton/day

- Yes

- Customized

- Customized Millimeter (mm)

- Stainless Steel

- Automatic

- 1 Millimeter (mm)

- No

- Mining Stone Jaw Crusher

- Customized

- 50 Hertz (HZ)

- 3000 Watt (w)

- Customized Kilograms (kg)

- 1000 Millimeter (mm)

- Customized Millimeter (mm)

Mining Stone Jaw Crusher Trade Information

- Tianjin port, Shanghai port

- Western Union Cash Against Delivery (CAD) Letter of Credit (L/C) Telegraphic Transfer (T/T) Paypal Letter of Credit at Sight (Sight L/C)

- 15 Set Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Export Packaging

- Australia North America South America Eastern Europe Western Europe Middle East Central America Asia Africa

- All India

- CE

Product Description

Description Of Mining Stone Jaw Crusher

Through cyclical movement of mobile jaw that swings around fixed jaw, materials between the two jaws are extruded, which causes crushing effect.

Feature Of Mining Stone Jaw Crusher

Large reduction ratio, optimum design of cavity, and high crushing efficiency. High revolution speed of mobile jaw and curved jaw plate make high production capacity.

Application Of Mining Stone Jaw Crusher

Mining Stone Jaw Crusher is widely used in mineral processing, building materials, silicate and chemical industry. In mineral processing industry production, Mining Stone Jaw Crusher is commonly used for coarse and intermediate crushing of hard or medium hard ores.

What is Mining Stone Jaw Crusher used for?

Mining Stone Jaw Crushers are mainly used as primary crushers.

Their main purpose is to reduce the material to a small enough size that it can be transported by conveyors to the next crushing stages. As the name suggest, jaw crushers reduce rock and other materials between a fixed and a moving jaw.