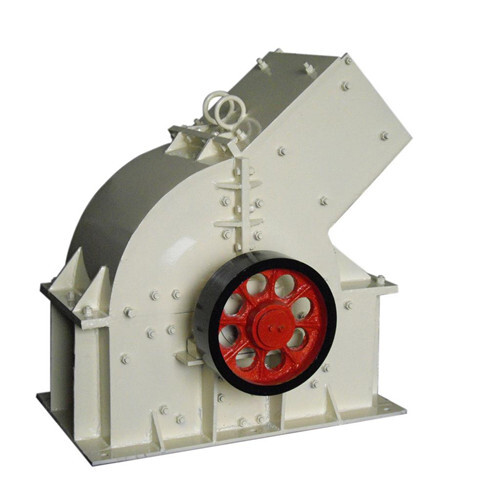

Quarry Plant Crushing Rock Hammer Crusher

Product Details:

- Type Quarry Plant Crushing Rock Hammer Crusher

- Material Stainless Steel

- Capacity 1000 Ton/day

- Computerized No

- Automatic Grade Automatic

- Voltage 3000 Watt (w)

- Frequency (MHz) 50 Hertz (HZ)

- Click to view more

Quarry Plant Crushing Rock Hammer Crusher Price And Quantity

- 10000.00 - 50000.00 USD ($)/Set

- 20000 USD ($)/Set

- 1 Set

Quarry Plant Crushing Rock Hammer Crusher Product Specifications

- 50 Hertz (HZ)

- 1000 Millimeter (mm)

- Customized Millimeter (mm)

- No

- 1000 Ton/day

- Customized

- Customized Kilograms (kg)

- 3000 Watt (w)

- Quarry Plant Crushing Rock Hammer Crusher

- 10 Millimeter (mm)

- Automatic

- Stainless Steel

- Customized Millimeter (mm)

- Yes

- Customized

Quarry Plant Crushing Rock Hammer Crusher Trade Information

- Tianjin port, Shanghai port

- Letter of Credit (L/C), Cash Against Delivery (CAD), Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T), Western Union, Paypal

- 15 Set Per Month

- 10 Days

- Contact us for information regarding our sample policy

- Standard Exporting Packaging

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Central America, Asia, Africa

- All India

- CE

Product Description

Description Of Quarry Plant Crushing Rock Hammer Crusher:

Quarry Plant Crushing Rock Hammer Crusher is composed of rack, rotor, sieve bar, hammer, etc. Motordrives rotor through transmission belt, and materials are crushed due to the collision between hammer and materials produced by the rotation of rotor.

Application Of Quarry Plant Crushing Rock Hammer Crusher:

Quarry Plant Crushing Rock Hammer Crusher is suitable for crushing materials such as coal, gypsum, alum,and limestone. The compressive strength of materials is no more than 1000 kg/cm2, and the humidity is no more than 15%.

How does a Quarry Plant Crushing Rock Hammer Crusher work?

Quarry Plant Crushing Rock Hammer Crusher mainly breaks materials by the impact of hammers. After that, the material smaller than the gap of the grate screen is discharged, and the material with larger particle size is bounced back to the lining plate and crushed by the additional impact of the hammers.